About this article

- World’s first Charge-as-you-drive highway on major Paris freight corridor

France’s A10 is now home to a groundbreaking showcase that wirelessly powers a truck, bus, utility van and passenger car at full speed—clear proof that electric road systems work in real highway traffic.

- France plans a 9,000-km ERS roadmap for clean freight

A nationwide study confirmed ERS as the most scalable solution for decarbonizing heavy transport, with 5,000 km planned by 2030 and 9,000 km by 2035. The A10 charge-as-you-drive project marks the first step toward this nationwide rollout.

- Freight electrification is stuck—and ERS unlocks it

Oversized batteries, massive power needs, limited space for chargers, high costs, and long charging stops are slowing the transition to electric trucks. ERS removes these barriers by delivering charge on the move. - Inductive tech changes the economics

With an average 200 kW of in-motion wireless power, trucks can start their route empty and finish fully charged, all while carrying smaller batteries. That means lighter vehicles, lower costs, fewer minerals—and no need for megawatt-scale rest-stop upgrades. Fleets stay on the move with zero detours.

Charge-as-you-drive: the first highway that charges a truck in motion

Imagine you’re an electric truck driver in 2030: 40 tons of apples loaded, cruising from Orléans to Paris at 90 kmh—and you never stop to recharge. No wandering around a rest area looking for a megawatt plug. No endless line of trucks waiting their turn. No dispatcher quietly panicks about where both you and their apples have gone.

Today? We’re much closer than you think.

Electric Road Systems (ERS) aren’t sci-fi anymore—they’re here, they work, and they’re already showing how naturally roads themselves can power vehicles in motion. Thanks to inductive technology built into the highway, vehicles don’t just power their engines in real time—they recharge their batteries as they go. For every kilometer driven, about one kilometer of energy is recovered, allowing trucks to leave the highway with a full battery. Heavy-duty trucks receive roughly twice the energy they consume, and light vehicles up to three times—far beyond simple energy balance. The result: freight that moves without oversized batteries, range anxiety, or long charging stops.

This blog explores the breakthrough results from France’s “Charge as You Drive” project on the A10 highway—the world’s first public demonstration of a truck charging wirelessly while driving at full highway speed. This 1.5-km wireless ERS section, powered by Electreon’s inductive technology and deployed with VINCI Autoroutes, marks a major milestone for advancing the large-scale adoption of electric freight transportation. Building on insights shared by Pierre Delaigue, Director of Connected, Autonomous & Electric Mobility at VINCI Autoroutes, we take you through the story behind the project, the A10 landmark performance, and how these achievements feed into France’s national ERS roadmap.

Why freight electrification is stuck today

Let’s start with the obvious: if electrifying heavy trucks were easy, France wouldn’t have crawled from just 904 electric trucks sold by mid 2024 to only about 2,000 today, out of roughly 600,000 total trucks. That’s not a transition; it’s barely a drop in a very diesel-heavy bucket. And it’s not for lack of interest. It’s because the hurdles—space, power, battery size, and cost—are still holding everything back.

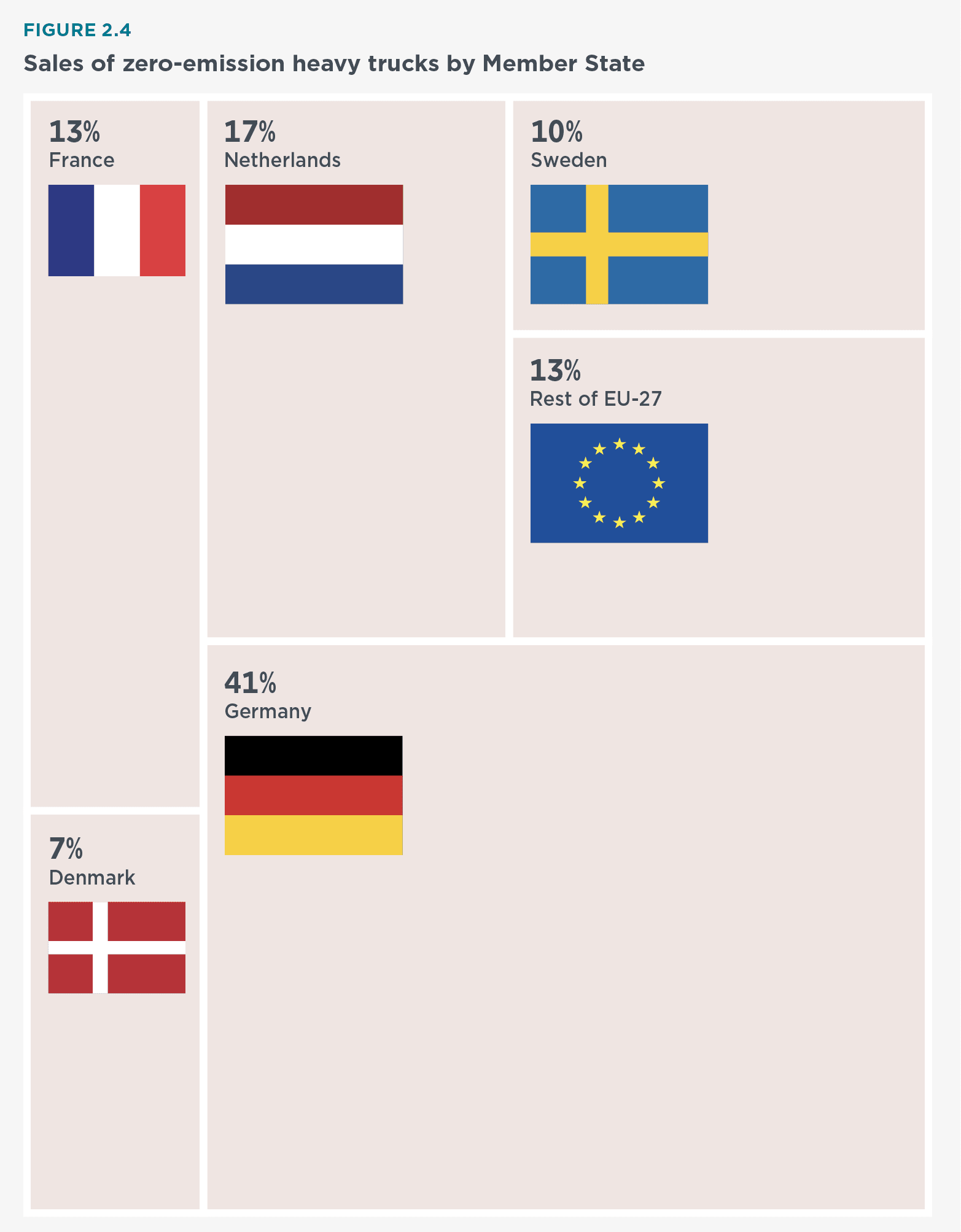

According to the ICCT, Europe is inching forward, with Germany leading at 41% of zero-emission truck sales in Q1 2024. France, meanwhile, sits at just 11%, and its heavy-truck market is still dominated by diesel and natural gas, even though battery-electric options are slowly gaining ground. In other words: things are moving… just not very fast.

Sales of zero-emission heavy trucks by Member State (Credit: The ICCT)

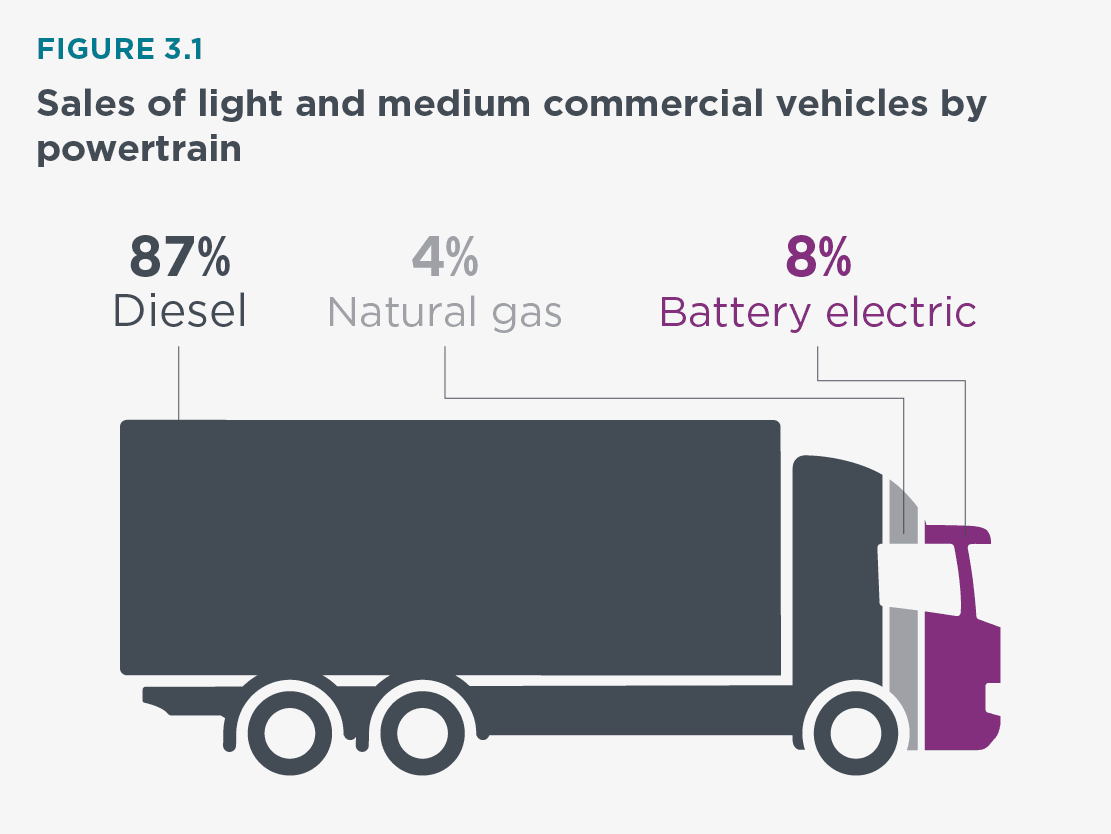

Sales of heavy trucks by powertrain (Credit: The ICCT)

And the biggest hurdles start with infrastructure. Delaigue notes that VINCI has already deployed more than 4,000 highway fast chargers across France’s highway network—a solid foundation. But to meet passenger-car demand alone, that number will need to multiply by eight by 2035. And for trucks—with bigger batteries, longer wait-and-charge times, and far higher power requirements—the real work hasn’t even begun.

The first challenge is space. High-power truck chargers require plenty of room because trucks need space to maneuver into position. Many end up parking awkwardly along curbs just to reach a charger—sometimes bumping into and damaging the equipment. Now multiply that across thousands of rest areas.

Then there’s power. A single busy rest stop offering high-power truck charging can require tens of megawatts—roughly the electricity needed to run an entire airport. Supplying that level of energy to every service area means new substations, major grid upgrades, long permitting cycles, and costs that climb fast.

And even if France magically solved both space and power, trucks would still face the battery problem. Diesel packs about 40× more energy per liter than lithium-ion batteries. To match diesel range, electric trucks need massive battery packs—heavy, expensive, slow to charge, and often produced in regions with carbon-intensive grids, dulling their environmental benefits from the start.

Smaller logistics operators feel this most. Buying a truck that costs three times more than a diesel model is hard enough. Add a huge battery that eats into payload—the thing that actually makes money—and the business case falls apart.

To put it simply: the trucks are too heavy, the batteries are too big, the power needs are enormous, the real estate isn’t available on highways—and the costs stack up fast.

No wonder freight electrification is moving at a crawl.

France’s roadmap for ERS-powered freight

To tackle the challenge of decarbonizing heavy trucks, France’s Ministry of Transport brought together experts from across the mobility world—OEMs, energy providers, highway operators, researchers—to answer one big question:

What’s the most practical way to clean up freight at a nationwide scale?

They compared all the major options: smaller batteries, hydrogen, biogas, biodiesel, oversized battery-electric trucks, and electric road systems (ERS). One solution stood out:

ERS—with smaller onboard batteries and charging while driving—offers the most efficient and scalable path forward.

Hydrogen and biofuels have roles to play, but not at the volume needed to serve an entire freight sector. And giant battery packs? They cost more, weigh more, slash payload, and demand an overwhelming amount of high-power charging infrastructure.

ERS flips the equation. Instead of trucks hauling massive batteries, the road supplies energy as they drive. Trucks get lighter, batteries get smaller, and the need for megawatt chargers at every highway stop drops dramatically.

That’s why the French government’s freight study points in a clear direction: a nationwide ERS network—5,000 km by 2030 and 9,000 km by 2035. The plan outlines electrified corridors stretching across the country, backed by an estimated €36 billion investment starting in 2025. What began as a technical project has now evolved into France’s roadmap for clean, continuous freight.

Why inductive ERS stands out

ERS comes in three configurations: overhead catenary lines (think trolley trucks), conductive rails set in narrow slots with exposed tops, and inductive coils buried out of sight beneath the asphalt. Catenaries work only for tall vehicles like trucks, and their overhead hardware, maintenance needs, and safety considerations make them less suitable for modern highways shared by many different vehicle types.

With catenaries out of the running for mixed traffic, that leaves two realistic pathways for a universal ERS: conductive rails and inductive coils.

Conductive rails are fully exposed to water, debris, snow, grime, and heavy truck traffic day and night. It’s a harsh environment for equipment that remains exposed 24/7.

Inductive coils, on the other hand, stay protected beneath the pavement and can deliver power to any vehicle equipped with a receiver—cars, vans, buses, and fully loaded trucks alike. These electrified highways can support the whole mix without visual clutter or exposed live components.

And once you have a single charging system that seamlessly powers every vehicle on the road, the next question becomes simple: how does it perform on a real highway?

The A10 project: proving ERS works at highway scale

Before committing to a nationwide shift, France needed one crucial answer:

Can wireless, in-motion charging really deliver enough power at true highway speeds?

The “Charge as You Drive” project delivered that answer—loud and clear.

VINCI Autoroutes and Electreon installed a 1.5-km inductive charging segment directly on a live highway near Paris. This wasn’t a quiet test track—it was the real world: full-speed traffic, real weather, a heavy truck, bus, van and car, and nonstop mechanical stress along one of France’s busiest corridors.

Beneath the asphalt, inductive coils and power units were linked to the medium-voltage grid. Once installed, a truck, bus, passenger car, and light commercial vehicle began gliding over the coils—charging in motion exactly as intended.

Then came the breakthrough moment.

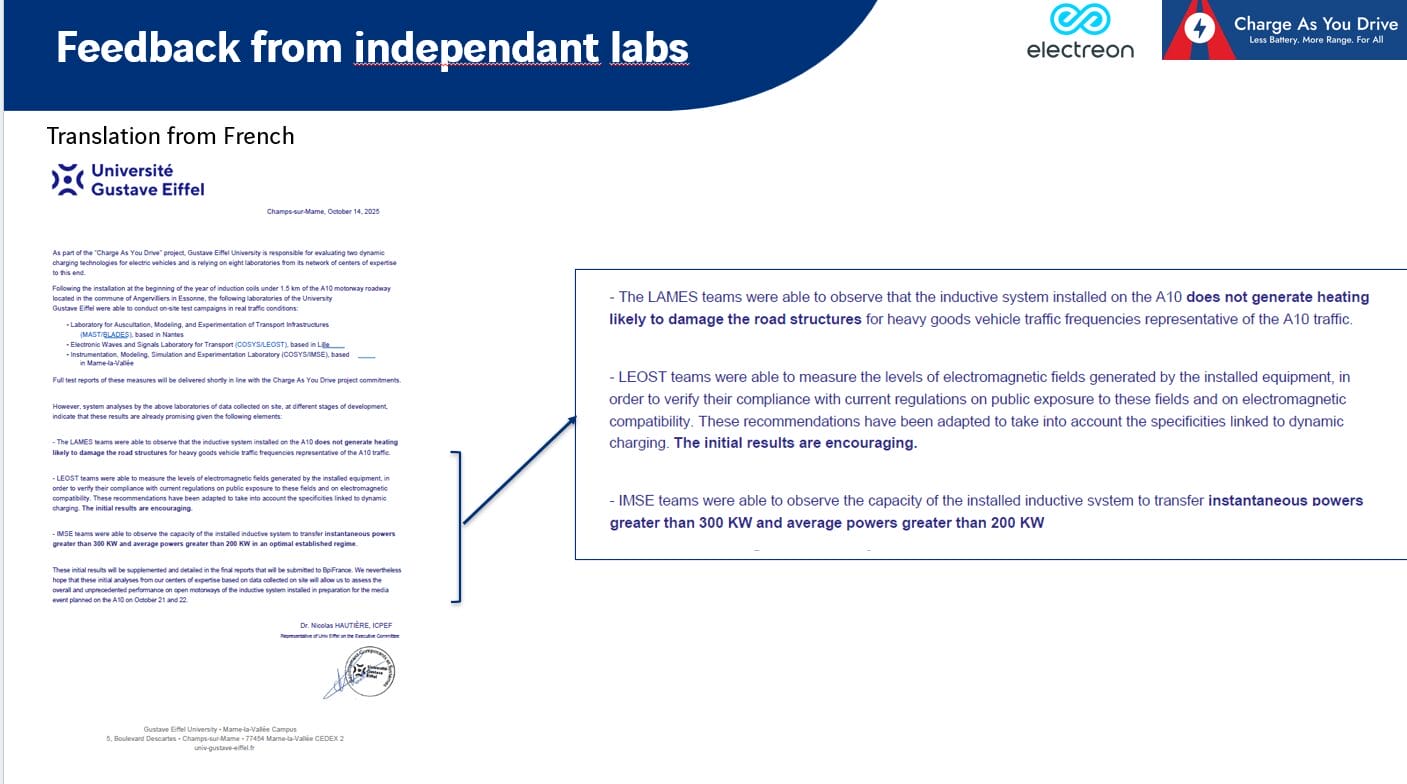

Independent researchers at Gustave Eiffel University measured the system and found that it delivered more than 200 kW of average power at 85–90 kmh, true highway cruising speed. Even better, it maintained safe EMF levels and showed minimal thermal impact on the road surface. And critically, the truck wasn’t just powering its motor—it was charging its battery at the same time.

And behind these results was a rigorous validation process: stringent lab and closed-track testing by Gustave Eiffel University confirmed the system’s safe operation at highway speeds and verified that inductive charging does not impact the road structure.

Thanks to the inductive coils embedded in the highway, the vehicle can recover about 1 km of energy for every 1 km driven. In practical terms, trucks can enter the highway with a low battery and leave with a replenished—or even full—one. That’s not just keeping up with energy consumption; it’s flipping the entire energy equation in favor of the vehicle.

In plain terms: inductive ERS can deliver the power trucks actually need—on a real highway, under independent validation, in everyday operating conditions.

VINCI called the A10 results “promising initial findings,” noting that the system provided high, stable power despite real traffic, weather, and wear.

And the impact goes far beyond one 1.5-km stretch.

Future implications for France

This project shows that wireless ERS isn’t just technically feasible—it’s ready to play a major role in the country’s freight decarbonization strategy. It proves that the technology can scale from a single highway segment to a full network of electrified corridors.

Why charge-as-you-drive reshapes freight economics

Once a highway can charge vehicles as they move, the entire freight equation flips in your favor.

For fleets:

• Trucks run full shifts with zero detours

• Smaller batteries = lighter trucks and higher payload

• Fewer charging mistakes and lower operating costs

For OEMs:

• Smaller battery packs reduce production costs

• ERS fits naturally into existing electric truck plans

• No need to depend on alternative fuels with uncertain supply

For regulators and governments:

• Fewer imported batteries and fewer critical minerals

• Less land needed compared to massive charging hubs

• A scalable path to zero-emission freight built into existing roads

And what about the cost? France already has a handy solution: toll concessions. ERS is not only financeable by toll revenue, it also costs only a fraction of what it takes to build a new highway. VINCI finances major upgrades—and that now includes ERS deployments—through concession-based toll models already proven across Europe. VINCI is now preparing to scale from the 1.5-km project to full ERS corridors of 50–200 km across different highways. The first step is a study into a potential 100-km deployment on the same A10, along the busy Orléans–Paris section that serves 5,800 trucks a day. Fleets will pay by the kilowatt-hour—simple, transparent, and easy for operators to manage.

Seven projects, one blueprint: ERS momentum goes global

Since the A10 went live, delegations from logistics operators, government ministries, OEMs, and infrastructure authorities have been lining up to see it in action. And there’s a good reason: the A10 tackles the exact problems every country is wrestling with—grid limitations, land constraints, charging bottlenecks, ballooning battery sizes, and the mounting pressure to cut freight emissions without slowing down supply chains.

What makes this moment even more exciting is that VINCI and Electreon now have seven joint ERS projects across Europe, giving the industry a real-world look at what future highway-scale electric corridors can become. These projects are already forming a repeatable playbook for regions aiming to electrify freight without waiting decades for massive grid upgrades or acres of new charging sites.

And the momentum isn’t limited to France. Across Europe and North America, ERS deployment is accelerating—especially inductive systems. Because when the charging hardware is safely tucked beneath the pavement, it becomes something close to magic: invisible, durable, weatherproof, and compatible with every type of vehicle on the road—cars, vans, buses, and the heaviest trucks.

Taken together, the lessons from these seven projects are shaping a practical, scalable blueprint for clean, continuous, charge-as-you-drive freight mobility—one that works seamlessly with the roads we already have.

The road ahead: when the highway becomes the charger

Decarbonizing heavy-duty transport isn’t optional. Nearly 90% of goods in France travel by truck, so cleaning up freight might be one of the biggest climate wins available. ERS goes straight after the toughest obstacles: oversized batteries, long charging stops, limited space for new infrastructure, and the huge power demand crammed into highway rest areas. It also fits naturally with national climate plans—and aligns with where truck manufacturers are already headed.

And the A10 shows what that future looks like: dynamic wireless charging works today—in real traffic, real weather, and at full highway speed. VINCI found that large-scale ERS could cut several tons of battery weight per truck, lowering costs, improving payload, and reducing lifetime emissions. France’s own analysis reinforces the point: ERS-enabled freight could slash CO₂ by up to 86% compared with diesel.

In practice, ERS turns highways into rolling charging corridors—letting trucks top up as they drive, skip long queues, and finish routes with more energy than they started—all while using smaller depot chargers for the first and last miles.

As more ERS corridors switch on, technology and policy are finally aligning. Europe’s busiest routes may soon double as clean-freight corridors, with France leading the charge.

ERS won’t just help trucks navigate the energy transition—it may be the key to scaling clean freight nationwide.

FAQs

What exactly is an Electric Road System (ERS)?

A system that charges electric vehicles while they drive, using coils embedded under the road. Think of it as a highway that doubles as a charger.

What makes the A10 project so groundbreaking?

It’s the world’s first public highway where a truck, bus, van, and car have all charged wirelessly at full speed, with 200–300 kW performance independently verified. These capabilities were validated through stringent lab and closed-track testing by Gustave Eiffel University, confirming safe highway operation without impacting the road’s integrity.

How does inductive charging work under a highway?

Coils under the asphalt create a magnetic field. Vehicles with a receiver pick up that energy instantly and charge while they drive.

Does ERS work in rain, snow, and real traffic?

Yes. The A10 tests ran under real weather and full highway traffic. Power delivery stayed strong, safe, and stable.

Why not just use megawatt chargers?

Space, cost, and grid demand. A single busy rest stop could need the power of an airport. ERS spreads demand across the whole route—no megawatts in one spot.

Is ERS compatible with all vehicle types?

Yes—cars, vans, buses, and heavy trucks can all use inductive ERS. That’s a major reason VINCI and the French government favor induction.

Is the technology safe?

Independent researchers confirmed safe EMF levels, minimal thermal impact, and no interference with nearby electronics or road users.

How will ERS be funded?

Primarily through toll-road concessions. Highways already use this model, and ERS fits right in—fleets simply pay per kWh of energy they use, much like paying standard tolls today.

When will we see full ERS corridors?

France is studying 50–200 km deployments now, starting with a 100 km stretch on the A10. The national plan targets 5,000 km by 2030 and 9,000 km by 2035.