In this article

- Cut the cords, keep the cargo moving:

Plug-in chargers slow ports down. Wireless charging keeps tractors, cranes, and yard trucks powered up on the go—no cables, no grid headaches. - Work smarter, not slower:

Charge during breaks or while rolling—no waiting, no bottlenecks, just smooth operations and full shifts. - Cleaner air, calmer grids:

Less diesel, fewer peaks, and lower emissions mean healthier ports and happier budgets. - Power that scales:

Electreon’s wireless tech spreads energy use evenly, trims infrastructure costs, and grows with your fleet—ready for whatever’s next.

The port power crunch

Ports are moving fast into the electric era—terminal tractors (UTRs, or utility tractor rigs), RTG cranes, and other heavy haulers are plugging in. But traditional plug-in charging—and the hefty space, cost, and grid upgrades it demands—is slowing the transition. A study at California’s Port of Long Beach shows that hitting zero emissions would require massive charging and grid build-outs, stretching both budgets and operations.

Meanwhile, ports never sleep. A single terminal may run 25–100 tractors on double shifts, shuttling containers over short routes all day. Most electric tractors can’t comfortably power through two full shifts without long charging breaks. Each unit can burn 100–200 kWh per shift—so queues, downtime, and “who’s-plugged-in-where?” coordination start to snowball. Add peak-demand charges to the mix and productivity (and OPEX) take a hit.

The upside is huge: NACFE estimates that if every terminal tractor in the U.S. and Canada went electric, ports would need ~726 GWh/year—avoiding nearly 930,000 tons of CO₂. The ICCT projects port electrification could cut more than two-thirds of fine-particle pollution and deliver over $150M in annual health benefits across major U.S. ports. The stakes are clear—now the charging model has to catch up.

How wireless charging keeps the cargo moving

Picture this: terminal tractors and RTG cranes recharge right where the work happens. Electreon’s wireless system delivers power in the flow of operations—no cables, no detours.

With Electreon’s wireless charging, ports get two clever ways to stay powered up:

-

Stationary charging tops up vehicles during natural pauses—like shift changes, short breaks, or while waiting in line.

-

In-motion charging powers vehicles through coils embedded under terminal roads, letting them charge as they move.

The effect: tractors and RTGs charge while hauling, stacking, or waiting—turning the road itself into shared infrastructure that serves cranes, tractors, and trucks at once. With no cords to manage, equipment moves freely and operations keep rolling.

It’s not just smoother—it’s smarter. A single flexible network spreads energy use throughout the day, avoiding grid peaks and trimming infrastructure spend. With 90%+ efficiency and 99.9% uptime, Electreon keeps fleets mission-ready, reduces battery size, and helps ports capture the financial, operational, and air-quality wins of electrification—without missing a beat.

Up next: Your step-by-step plan for port electrification.

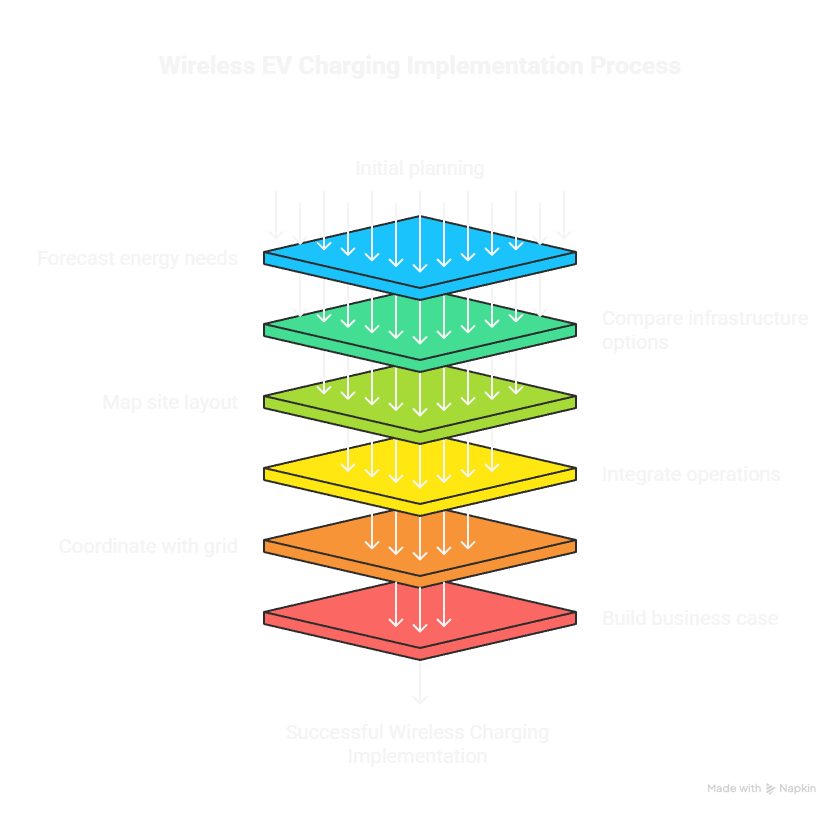

Your step-by-step plan for port electrification

Planning a wireless charging rollout at a busy port can feel like steering a container ship through a narrow channel—there’s a lot to balance, but once it’s lined up, everything flows. Here’s how planners can design, fund, and future-proof a charging ecosystem that keeps operations running smoothly.

Step 1: Forecast the load

Start with the math. Estimate how many terminal tractors and RTG cranes you’ll power, how many shifts they run, and how much energy they burn—about 100 to 200 kWh per shift is typical. Factor in on-route wireless charging to cut plug-in demand and lighten the grid load.

Plan for growth: as TEU throughput (the number of 20-foot container units handled) rises, so will energy demand. For context, the Port of Los Angeles handled 8.6 million TEUs in 2023, each representing a 20-foot container.

Step 2: Compare your infrastructure options

Lay out your choices: banks of plug-in ultrafast chargers, or a wireless system combining stationary and on-route charging. Weigh the trade-offs in CAPEX, OPEX, maintenance, and downtime. Wireless charging avoids damaged cables, minimizes handling risks, and reduces reliance on costly battery-energy storage for peak shaving.

Step 3: Map the site layout

Think spatially. Where can you embed stationary charging points at depots or dwell zones? Where will your on-the-move segments run—along that loop between the ship-to-shore cranes and the intermodal yard? Plan for easy access, maintenance, and civil works integration. Electreon’s vehicle-agnostic design means one system can charge any battery type—from tractors to RTGs.

Step 4: Integrate with daily operations

Charging should blend into the rhythm of work. Align shift changes and dwell times with stationary charging, and design routes so vehicles naturally pass over energized segments. Tie everything into fleet telematics for smart monitoring and optimization.

Step 5: Coordinate with the grid

Every electrification story begins with the grid. Review your demand charges, tariffs, and transformer capacity, and collaborate closely with utilities and port authorities. Wireless charging smooths energy peaks by spreading demand throughout the day—a win for uptime and stability.

Step 6: Build the business case

The math speaks for itself. Instead of spending $8–10 million on plug-in chargers, ports can install wireless infrastructure for about $4–5 million—one shared system for the entire fleet. Add higher uptime, lower maintenance, and fewer human errors, and the ROI becomes obvious. The environmental gains are just as strong.

Step 7: Plan for risks and resilience

Every system needs a safety net. Factor in technology maturity, integration with legacy infrastructure, and long-term maintenance. Dual-mode wireless charging (stationary + on-the-move) adds redundancy—if one element goes offline, your fleet keeps moving.

Step 8: Navigate regulations and funding

Electrification doesn’t happen in isolation—it’s powered by policy. Explore national and international incentives, including U.S. infrastructure funding for port decarbonization. Many programs now support zero-emission cargo-handling and charging systems for RTGs, tractors, and yard trucks alike.

Step 9: Model the impact

Imagine a fleet of 50 terminal tractors and a handful of RTG cranes, each using hundreds of kWh per shift. With wireless charging, that energy demand spreads smoothly across the entire shift—not just during short breaks. Use this kind of modeling to build a solid business case and show how the benefits stack up in the real world.

From lessons learned to power well earned

Ports run best when everything connects—and so should your charging strategy. The strongest electrification projects link vehicles and infrastructure through one seamless wireless system that keeps energy flowing and operations nonstop.

For planners, success starts with clear goals, smart design, and the right partners to bring it all to life. In a world where every shipment and kilowatt counts, the ports that lead early will move ahead the fastest.

Let’s get your dock wireless-ready. Reach out to our team to get started.

FAQs

How does wireless charging actually work at ports?

Electreon embeds charging coils under terminal roads and in dwell zones. Energy transfers wirelessly to vehicles as they drive or pause—no plugs required.

Can heavy-duty vehicles really charge while moving?

Yes! Terminal tractors, cranes, and yard trucks get steady power along electrified routes, charging through every shift.

Is it efficient?

Absolutely—Electreon’s system delivers 90%+ efficiency and 99.9% uptime, matching top plug-in chargers without the hassle.

What’s the biggest win for ports?

Continuous operation. Vehicles charge as they work, cutting downtime and infrastructure costs while keeping cargo moving.

Where is this already happening?

Electreon’s tech is live in the U.S., Europe, and Asia—including Michigan’s public wireless road and UCLA’s electric shuttle fleet.