In this article

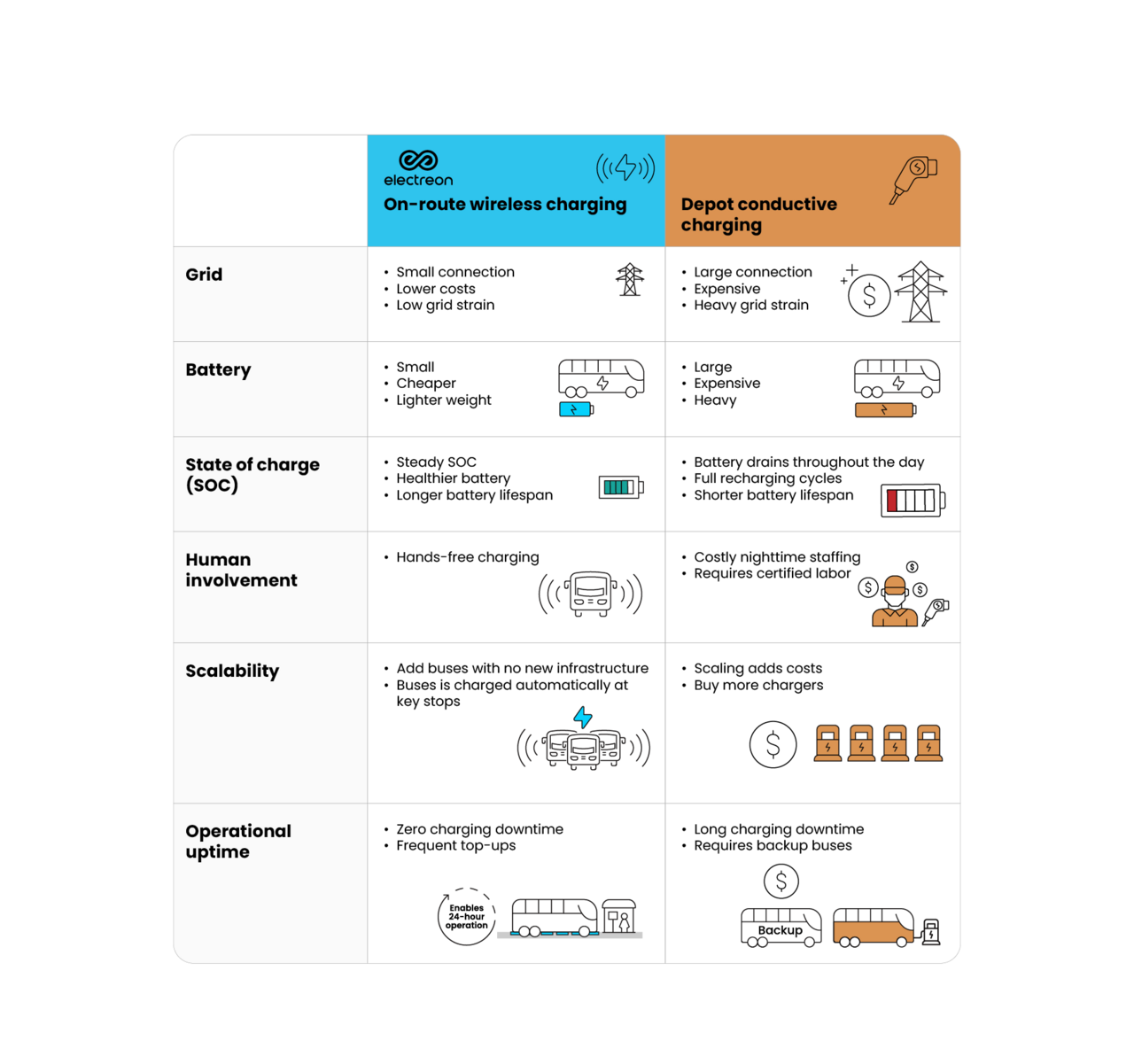

Wireless charging is a total power shift for bus rapid transit (BRT) systems. It keeps buses charged on the move, allowing for smaller, lighter batteries and easing pressure on the grid. The charging infrastructure stays hidden underground—no plugs, cables, or clutter in sight.

Buses no longer waste time returning to depots or wrestling with heavy connectors. Instead, wireless charging at key bus stops keep entire fleets running all day. And with a many-to-one setup—one system serving multiple buses—cities save big on chargers, space, and standby vehicles. The result? Cleaner air, quieter streets, and transit systems built to grow with the cities they serve.

The workhorse of urban transit

Bus rapid transit (BRT) systems now keep nearly 200 cities moving—including 16 in the U.S.—carrying over 32 million riders a day. These rapid bus lines move crowds quickly, reliably, and for a fraction of the cost of new rail or subway lines.

And the need’s only growing. By 2050, over two-thirds of the world will live in cities, up from about 55% today. That’s more people to move, more congestion, and more pressure on transit systems to deliver speed and affordability. No wonder BRT networks are spreading fast—they’re often the smartest, most cost-effective way to boost capacity in booming cities.

Why charging e-buses can make or break BRT

As BRT systems go electric, keeping them charged becomes the real challenge. With zero-emission mandates on the horizon, operators can’t afford clunky, costly, or grid-straining solutions. Charging needs to be reliable, scalable, and synced to the nonstop rhythm of BRT.

That’s where wireless charging flips the script—turning everyday routes into charging zones. Here’s the surprising part: Just a few cleverly-placed charging spots along the route and at end stops—can keep the entire fleet moving. Instead of buses waiting to charge, the charger meets the bus.

Up next, we’ll explore five proven ways this approach boosts BRT efficiency—and why it’s the smarter way forward.

1. Charging that works for the fleet—not the other way around

It’s early morning and one bus never got plugged in overnight—so it’s stuck in the depot instead of on the road. It happens more often than you’d think. Add in broken cables, glitchy chargers, and long queues straining the grid with ultra-fast charging, and the whole operation slows down. Even when everything works, drivers still waste time returning to depots to recharge and wrestling with heavy plugs—labor that adds up fast.

Today’s charging asks fleets to adapt: restructuring schedules, redesigning depots, and compromising operations just to make the system work. But charging should support fleet needs—not limit them.

With wireless tech, the charger meets the bus in the lane. No cables, no waiting, no interruptions. Buses glide over coils hidden beneath the road, and energy flows quietly, automatically. During that quick stop to pick up or drop off passengers, charging happens in seconds—turning every pause into progress and keeping routes, schedules, and cities moving exactly as they’re meant to.

2. Electreon’s triple-play charging scheme

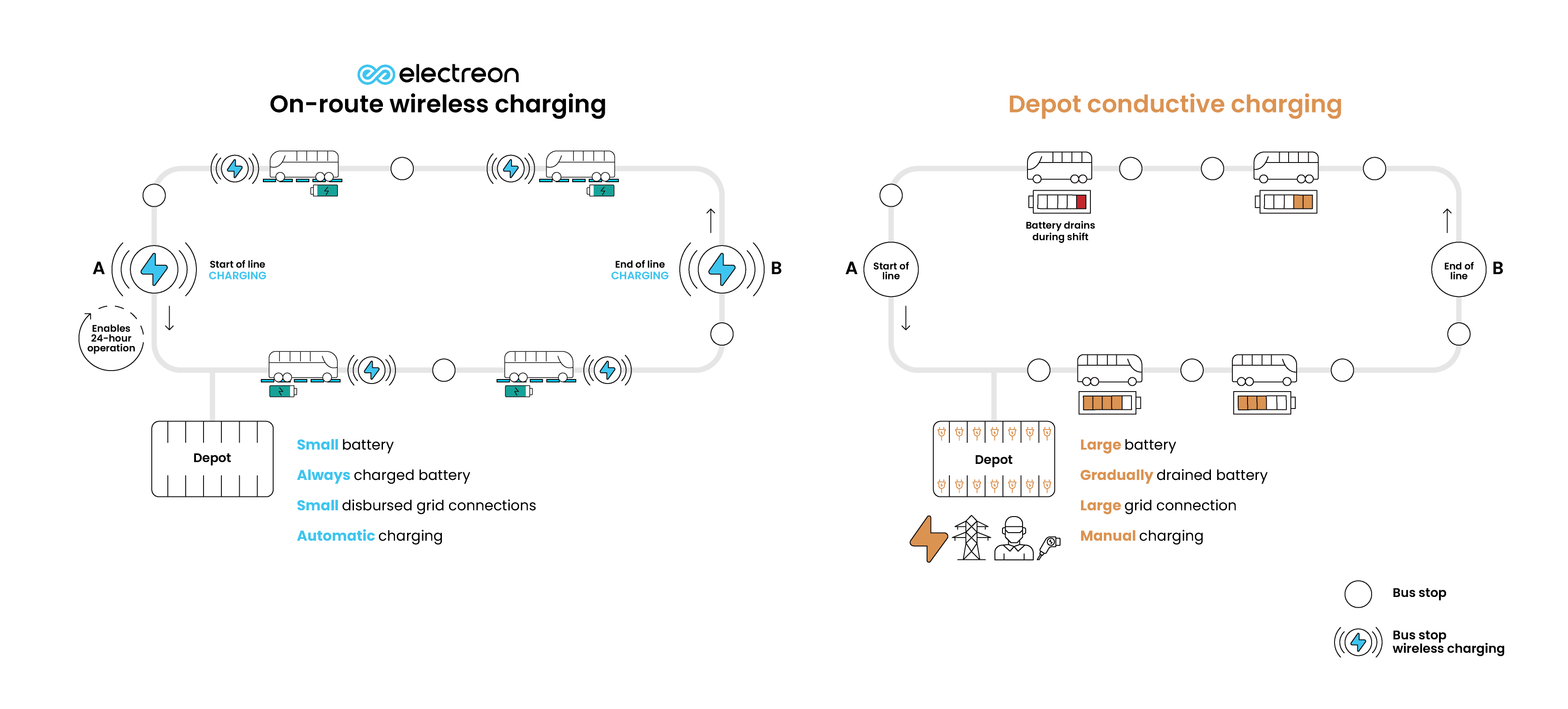

Electreon doesn’t throw coils around like confetti. Its solution is carefully designed around three complementary charging setups: terminals, bus stops, and depots.

Terminals: At the end of each loop—where every route begins again—terminals deliver the biggest boost: Just five to ten minutes of wireless top up before the next run, and buses absorb most of their daily energy, while drivers grab a quick coffee. Over a typical BRT day, with 10 to 12 loops, those short boosts add up to around an hour or more of charging—enough to keep buses rolling nonstop without ever running on empty.

Bus stops: BRT buses usually pause for 20 to 60 seconds at each stop, and Electreon turns those moments into quick top-ups. A single stop can add enough energy to extend its range by roughly 1 to 1.5 kilometers, depending on the model, weather, and terrain. Because stops are frequent, these little power boosts stack up fast—each one adding up to 5–10 minutes of opportunity charging across the day. And here’s the clever part: just a few short wireless segments at key stops can keep the whole fleet charged. When opposite stops sit close together, a single underground unit can even power both directions—double the value, half the hardware.

Depots: This is where Electreon rewrites the rules. Daytime on-route charging slashes—sometimes even eliminates—the need for overnight depot charging altogether. No more sending buses back just to plug in. Instead, they roll into the depot with a high state of charge (SOC), needing only slow, low-cost top-ups—or none at all. The coils and management units stay neatly underground, so there’s no tangle of plugs, no fleet of fast chargers, and no grid-crunching demand spikes. The result? Fewer chargers, less charging time at night, and a lighter load for both the budget and the grid.

Together, these three modes create an easy, self-sustaining rhythm: a quick hit at terminals, a sip at stops, and—if needed—a calm finish at the depot. The system keeps buses topped up, batteries light, and the city moving, all without breaking stride.

3. Why carry all that battery?

Large batteries are the elephant on every e-bus—they’re heavy, costly, and resource-hungry. At around $140 per kilowatt-hour, a 750 kWh unit can run close to $100,000.

With Electreon, buses don’t need to haul that extra weight. Because much of the charging happens wirelessly throughout the day—at terminals and stops—the onboard battery can shrink from 700+ kWh to about 300-350 kWh. That’s roughly $50,000 in savings per bus, plus lower weight, better efficiency, and less wear on tires and roads.

As opposed to IMC trolleybuses, which charge while moving but rely on overhead cables and costly upkeep, Electreon keeps the same freedom to move and charge—without the visual clutter or expensive maintenance. The system stays hidden under the road, quiet, reliable, and out of sight.

Smaller batteries also mean reduced demand for critical minerals, and lighter load on the grid. Instead of powering entire fleets overnight, charging is spread across the day. At the BRT in Trondheim, Norway, simulations showed Electreon’s approach could cut infrastructure and energy costs by 30–40% compared to plug-in charging—real money staying in city budgets.

4. One charger, many buses

No two BRT systems are alike. Some run tight 30-kilometer loops every five minutes; others stretch 50 kilometers with longer intervals. One line might have 10 stops, another 40—each offering anywhere from 20 to 60 seconds of opportunity charging.

Electreon designs each project with precision, running detailed simulations to find the sweet spot between cost, performance, and energy yield. The goal: keep buses running all day with minimal onboard storage. A typical layout mixes charging at terminals, select stops, and light overnight topups, allowing buses to operate with 250-300 kWh batteries—about half the size of conventional packs.

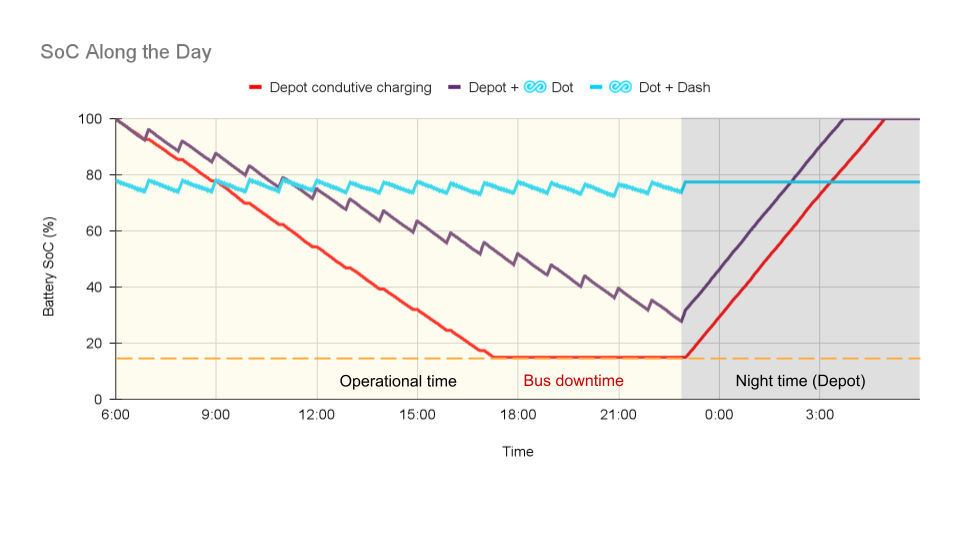

In a traditional setup using only plug-in depot charging (red line), the bus starts the morning at 100% and drains steadily, running low by early evening. With Electreon’s wireless solution that includes depot charging (blue line), the battery depletes more gradually—its sawtooth pattern showing quick top-ups at terminals throughout the day—keeping plenty of energy until the end of service. And with Electreon’s fully on-route wireless setup (yellow line), the SOC stays steady all day long—so consistent, in fact, that depot charging isn’t needed at all.

Simulation of bus battery SOC: Red: Depot-only conductive charging runs out by evening, then charges at the depot; Purple: Electreon with on-route plus depot charging stays charged all day and supplements at the depot; Blue: Electreon’s fully on-route charging keeps a steady SOC 24/7 without depot charging needed.

To power an entire fleet, Electreon only needs to electrify around 10–20% of the route. That’s enough to keep buses topped up all day, and rolling back to the depot with a high state of charge (SOC). Peak overnight demand drops from roughly 1.5 MW to just 500 kW.

And with one charging system serving multiple buses, operators save big—no need for one-to-one chargers or standby backup vehicles. Fleets can run continuously like diesel systems—just cleaner, quieter, and far more efficient.

5. Built to grow

Cities don’t have to make huge investments from day one. With Electreon, they can start small—charging at depots or terminals—and scale up as fleets expand. That flexibility makes the system not just practical, but politically painless.

One of the joys of wireless charging is that you hardly notice it. Unlike bulky plug-in stations or spaghetti overhead wires, Electreon’s coils stay hidden underground—safe from weather, wear, and curious hands. Once they’re in place, the hard work is done. No tearing up sidewalks or rewiring the city when new buses or routes are added—they simply glide over the coils and charge, like the infrastructure was there all along.

And because power is distributed across many points, the system comes with built-in backup. One hiccup won’t stop service—it’s like having invisible chargers stitched into the road, always ready to keep the fleet moving.

Beyond efficiency: cleaner air and happier riders

The cost savings are big, but no less of a win is the human story. Wireless charging keeps buses electric all day—delivering cleaner air at stops, quieter streets, and smoother rides. Pair it with renewables, and you’ve got a transit network that’s modern, green, and built for the future.

For residents, it means fewer fumes and healthier lungs. For riders, it means on-time buses without surprise charging delays. And for city leaders, it’s a clear path to climate goals—proof that public transit can be cleaner, quieter, and better for everyone on board.

Curious how much your BRT could save? Electreon maps the smartest charging plan for your routes—showing ROI and cutting costs. Contact us.

FAQs

What makes wireless charging a “game-changer” for buses?

It keeps buses charged while they’re working—not waiting. No more plug-ins, downtime, or charging queues.

Do buses really charge while moving?

Yes! Dynamic charging lets buses pick up energy as they drive over electrified road sections.

How long does a bus need to stop to charge?

Just 20–60 seconds—about as long as it takes to drop off and pick up passengers.

Does the whole route need to be electrified?

No. Only 10–20% of the route needs coils to power an entire fleet. A little road electrification goes a long way.

What happens if one charging spot fails?

No panic! Power’s distributed across many points, so one hiccup won’t stop service.

Are these chargers visible?

Not at all. Everything’s underground—no messy cables or spaghetti wires hanging over the street.

How does this compare to IMC trolleybuses?

Same freedom to move and charge, but without the visual clutter of overhead wires or the high maintenance costs.

Is this good for the grid?

Very! Charging’s spread throughout the day, easing peak demand and avoiding costly upgrades.

Can cities start small?

Absolutely. Start with terminals or depots, then scale as your fleet grows. It’s plug-free and politically painless.

What’s in it for riders?

Cleaner air, quieter streets, and buses that show up on time—because they’re always charged and ready to roll.